A suitable coating machine for every application

Various coating possibilities are available to cover all the different application cases:

- Direct emulsion

- Capillary film

- Pre-coated PCF mesh

Nowadays, the most frequently used method is direct emulsion coating. Important is, that the emulsion is standardized – automatically and reproducible – applied by a coating machine. The selected printing process determines the type and quality of coating. In this respect, the following parameters are of utmost importance:

- Coating thickness in micron (EOM)

- Surface roughness in micron (Rz)

- Resistance (water- or solvent-based ink)

- Necessary resolution / printing fineness

- Print run and print resistance

- At any rate, the use of the right kind of emulsion is a key factor that can save you a lot of money.

The choice of the appropriate coating machine is influenced by various key factors, such as:

- Screen size

- Screen quantity per day

- Sequence of operations

- Space available

- Budget

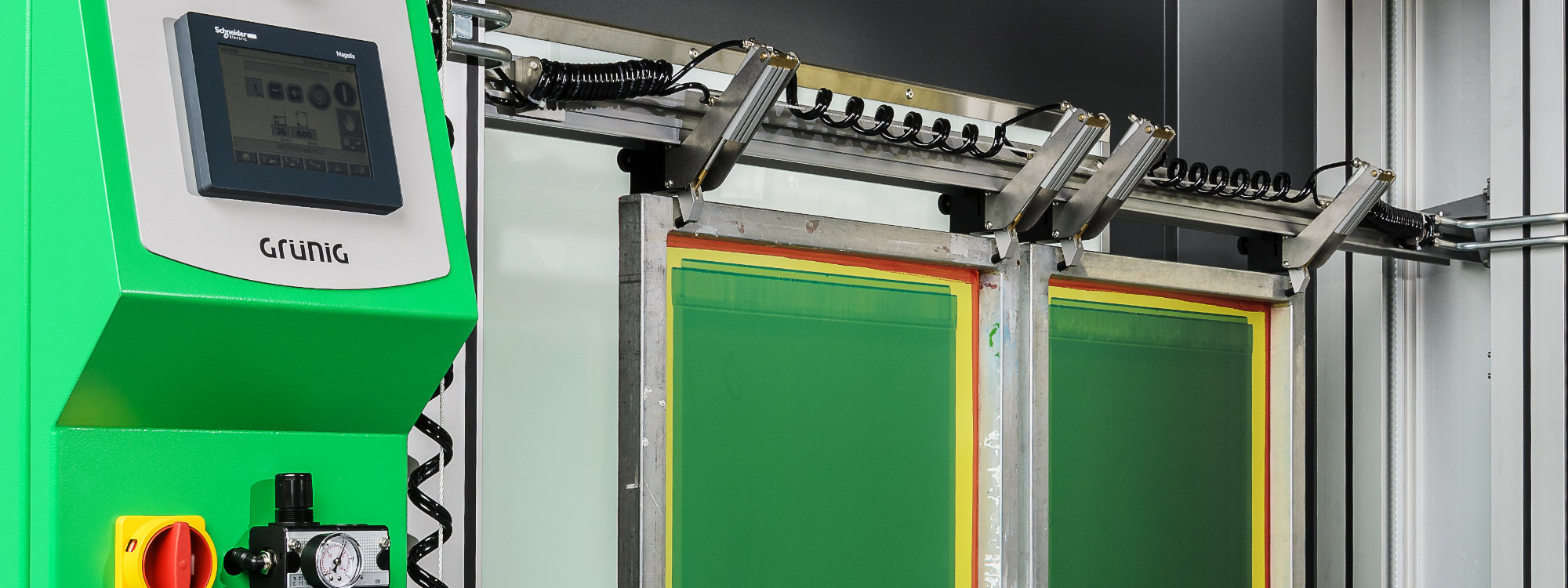

Automation thanks to magazine technology: The modular magazine systems have been designed for automatic loading and unloading of printing screens. These magazines complete all GRÜNIG IN-LINE systems in the G-WASH or G-COAT sectors. For practical purposes, this solution means: Upon loading the screens and starting the process, all the screens are automatically processed without any intervention from the operating staff.

DE

DE  EN

EN